1.1Recovery mechanism of repeated fracturing

Artificial cracks are always generated perpendicular to the direction of small horizontal stress

The stress field near the oil well will be changed due to various factors in the process of oil reservoir development. When the change reaches a certain degree, the directions of major and minor principal stresses will be deflected. Under the local stress change and certain fracturing construction conditions, the extension of repetitive fracturing fracture may also be changed relative to the original fracture.

Existing problems:

1.A single old seam repeatedly opens.

2.Too large scale is easy to flow.

3.Formation pressure drop, water cut rise and high recovery in the area near the original fracture.

4.Formation and fracture wall permeability decline.

5.Stimulation mechanism.

6.Re-open the original cracked crack.

7.Effective extension of the original crack system.

8.Re-filling proppant for original fracture.

1.2 Principles of Diversion Fracturing Technology

Diversion fracturing refers to that during fracturing construction, the bridge plugging effect of chemical directional plugging agent is applied to directional plugging of old fracture or added sand fracture, improving the static pressure at the bottom of the well, making the fluid deflect in the formation, forming a new fracture different from the direction of the old fracture or making the fracturing sand evenly distributed in the fracture, so as to open a new fluid flow channel in the reservoir, communicate the oil and gas reservoir not producing the old fracture in a larger range, and increase the oil and gas production, This process is known as diverting fracturing technology.

1.3 Technical ideas

High-strength positioning plugging fracture diversion fracturing technology researched by our company is mainly a process technology for repeated transformation of oil wells with high water content in oil reservoirs. Combined with selective water plugging technology and diversion fracturing technology, the basic principle is to firstly selectively plug water in water breakthrough oil layers, and plug the original fracture depth or the parts of reservoirs with increased water saturation due to the development of microfractures, Then, the diverting fracturing technology is used to implement the diverting fracturing in the near-well zone or the depth of the fracture, so as to achieve the purpose of creating a new fracture, so as to reduce the water content of the oil well, recover or improve the productivity of the oil well. The diverting agent is the key to determine whether the high-strength directional plugging and diverting fracturing process can succeed.

High-strength positioning and sealing fracture diverter is carried into the target horizon with sand carrying fluid during construction, which can form a high-strength artificial well wall at the formation temperature, so that the fracturing sand can completely enter the target horizon when the fracturing well is re-fractured, improving the re-fracturing effect. This product is produced with advanced hot coating technology and is loose under normal temperature. It is not only applicable to old well re-fracturing measures, but also applicable to various oil well fracturing water plugging measures.

Innovation Points

Combination of plugging and optimized re-fracturing: establish a new oil and gas flow channel with high conductivity, and communicate, transform and utilize the residual oil enrichment area and the reservoir with low producing degree or not producing to the greatest extent.

Seen from the field application effect, the high-strength positioning plugging fracture diverter can be consolidated to form a high-strength plugging under the formation temperature, so that the fracturing sand can completely enter the new fracture during the fracturing well re-fracturing, improving the re-fracturing effect. In the application of Jilin, Changqing, Jidong and other oil fields, the oil increase effect is obvious.

Project | technical indicators |

appearance | Loose granular |

Sieve analysis qualification rate (≤ 0.85mm) % | ≥90 |

Volume density g/cm3 | ≤1.25 |

Compressive strength (24h/60°C) MPa | ≥5.0 |

Permeability (24h/60°C) md | ≤50 |

Compressive strength (24h/90°C) MPa | ≥10.0 |

Permeability (24h/90°C) md | ≤20 |

Compressive strength (24h/120 ° C) MPa | ≥40.0 |

Permeability (24h/120 ° C) md | ≤5 |

Field Applications

Seen from the field application effect, the high-strength positioning plugging fracture diverter can be consolidated to form a high-strength plugging under the formation temperature, so that the fracturing sand can completely enter the new fracture during the fracturing well re-fracturing, improving the re-fracturing effect. In the application of Jilin, Changqing, Jidong and other oil fields, the oil increase effect is obvious.

1. High-strength positioning plugging and steering fracturing technology, sealing original fracture and turning to new fracture

Diversion fracturing process for test positioning and plugging of water flooded well layers: 5 wells and 5 layers; long-term plugging of cracks by using solidified resin sand; designed length of plugging section: 8-15m; concentration of resin sand in plugging section: 1-2m3/m.

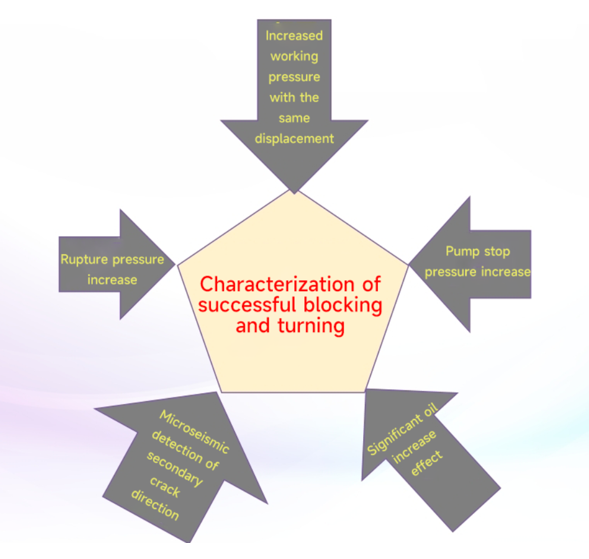

The fracturing steering is proved by construction pressure increase (2-9MPa), pump shutdown pressure increase (2-3MPa), water cut change (2% decrease) and post-fracturing stimulation effect (3x of conventional fracturing)

2. Oil well fracturing

The success rate of the process is 88.2%. The construction pressure and pump stop pressure increase significantly before and after the steering, and there is obvious fracture pressure after the steering. The crack monitoring results show that the cracks turn 25-68 °, meeting the steering requirements for sealing medium deep and medium shallow oil and water wells.

With the application of Well 34, the effective rate of the measure is 94.1%, and the effect is 1.3 times of that of the non-steering fracturing.

3.Water well fracturing

Ji 28-015 water well failed to inject, resulting in no energy supplement of surrounding oil wells, low liquid production and low oil production.

The well and surrounding oil wells are subject to fracturing in the same layer and forced to establish displacement relation. After fracturing, the oil-salvaging and drainage are all drilling mud, with normal water injection. Currently, the daily injection volume is 53 m3, and the injection capacity is 2 times of that before fracturing.

Synchronous fracturing of oil-water well in the same layer, water well diversion fracturing technology, well pattern reconstruction, and establishment of displacement relationship.

4.Water wells turn to fracturing, increase displacement direction, and fracture monitoring proves fracture turning; Fine silt support, making reasonable conductivity cracks

Normal water injection (daily injection of 68-70 m3) after well group pressure of Well 29 was conducted, and the average daily fluid increase of surrounding oil wells was 9.6t. The stimulation effect brought by the improvement of water drive effect was observed

Fracturing compound fast plugging control technology: block the fracture by pumping the plugging control agent to the design position, control water and increase oil.

Fracturing Full-Fracture Sealing Steering Agent

Generally, low-permeability reservoirs are characterized by discontinuity, heterogeneity, and anisotropy. To improve recovery efficiency, fracturing operation is usually adopted, in which the effect of temporary plugging and repeated fracturing is more obvious. Original fractures are sealed with full fracture sealing diverting agent and new fracture layers are opened on vertical and horizontal planes. This method has a good effect in stabilizing oil and controlling water, improving crude oil production and oil recovery. Therefore, it has a great prospect for the research on fracturing with full-fracture sealing diverter.

The fracturing full-fracture sealing diverter is a product organically combining the fracturing proppant and thickener. During fracturing and sand adding, the diverter and water are mixed in the sand mixer truck. The particles of the fracturing full-fracture sealing diverter can be quickly and stably suspended in the fracturing fluid system and enter the ground for fracturing to realize sealing. The fracturing construction is completed under the condition of saving a lot of manpower, equipment, and raw materials, making the fracturing simpler, energy-saving and environmentally friendly.

1. Product principle

This product adopts a new micro-expansive elastic material, which reacts with a specific initiator. Under the attraction of opposite charges of groups, the adjacent particles dispersed in the viscoelastic fluid show adsorption. The polymer chain relates to two or more particles to form a self-bridging structure, so it has the expansion characteristics.

2. Product advantages

This product has excellent water expansion characteristics, after expansion, it still has a certain flexibility, the expansion ratio can be adjusted, the expansion time can also be controlled according to different requirements, for various underground rock cracks to achieve effective full seam sealing, can continuously deform and fill with the gap, achieve tight sealing effect.

Product features: no sand-carrying liquid and no preparation in advance; Full fracture sealing of long well section.

The sand ratio range is adjustable (5% - 200%), with fast pressure rise and continuous construction; The sealing strength is 20-40MPa; Plugging time adjustable.

3. The fracturing full-fracture sealing diverter has the following properties:

1) The fracturing full-fracture sealing diverting agent can be used under the temperature of 0-120, and the full-fracture sealing can meet the construction requirements during the construction process.

2) The permeability of full-fracture sealing diverter used for fracturing is far lower than the formation permeability, to achieve the purpose of water plugging.

3) Low cost, simple operation, convenient construction, etc.

Strong suspending capacity of full-fracture sealing diverter for fracturing, ensuring on-production construction on site.

Full-fracture plugging diverter for fracturing within the range of 5% - 200% sand ratio can be produced according to the needs.