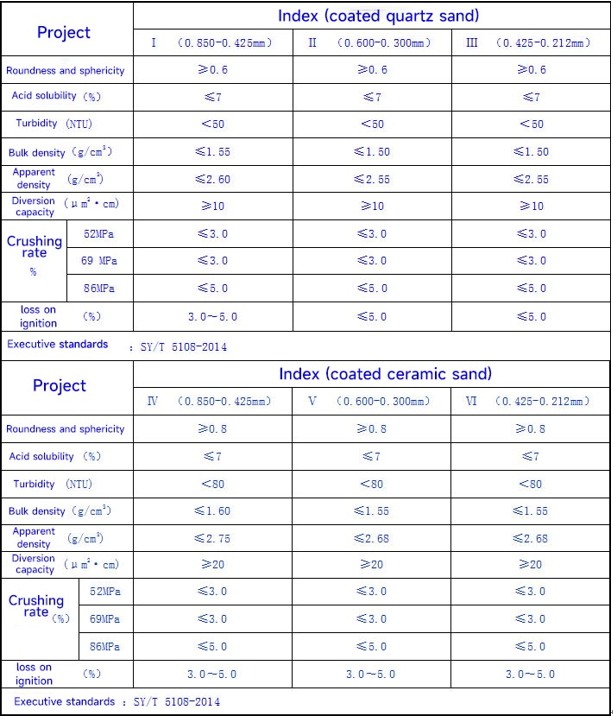

Fracturing proppant resin coated sand: according to the technical requirements of petroleum exploitation and fracturing, this product carries out macromolecular material coating on quartz sand or ceramists through the coating method, so that the compressive strength of quartz sand or ceramist can be greatly improved. It not only has high strength, low friction, and other characteristics, but also has water control capacity. It is especially suitable for the fracturing of oil and gas wells with high water content. Because the added macromolecular material has high temperature resistance, Therefore, it is applicable to the fracturing of deep oil and gas wells.

Fracturing proppants have the following advantages:

(1) The resin coating encapsulates the quartz sand or ceramists, increasing the contact area between the quartz sand or ceramists, thereby improving the ability of the proppant to resist the closing pressure.

(2) The volume density of resin coated sand is about 1.5g/cm3, which is lower than that of quartz sand and ceramists, convenient for suspension and carrying, and convenient for carrying with water.

(3) Resin coated sand is deformable, which increases the contact area, improves the bearing capacity of proppant, and prevents the proppant from being embedded in the formation to maintain high conductivity.

(4) Under the formation closing pressure of proppant, even if quartz sand or ceramists is broken in the formation, the resin thin layer can also wrap fragments and particles together to prevent them from migrating or blocking the pores of proppant zone, so that the fracture maintains a high conductivity.

Oil and water permeable under normal pressure

The field test results show that the proppant has good fracturing effect, water and oil blocking, strong anti-crushing ability and good diversion effect. Long term of validity after construction.

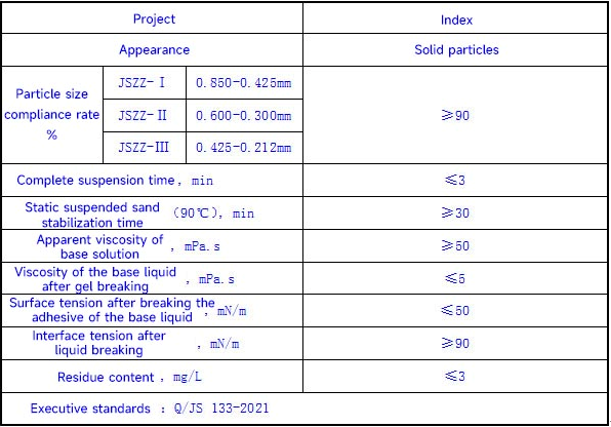

Self-suspending proppant

Self-suspended proppant organically combines proppant for fracturing with thickener and other additives through special technologies. During fracturing construction, self-suspended proppant and water are mixed in the sand mixer truck. A stable suspended fracturing fluid system is quickly established by the mesh interconnection structure formed between self-suspended proppant particles and the water. In a few minutes, the fluid preparation - crosslinking - sand mixing link in traditional fracturing construction is completed, which saves a lot of manpower, equipment The fracturing construction is completed under the condition of raw materials, making the fracturing more simple, safe, energy-saving, and environmental-friendly. The popularization and application of self-suspending proppant fracturing technology opens a new chapter on energy conservation and environmental protection of hydraulic fracturing technology.

Usage and precautions

During construction, the product can be carried into the stratum with clean water, reinjected water of oil field, ground rivers and lakes, rainwater, etc.

Packaging, transportation, and storage

1. The product is packed with woven bag lined with plastic film, with net content of 1000kg ± 2kg.

2. Handle with care during transportation to prevent exposure to the sun and rain and avoid mixed transportation with food.

3. Store in a cool and ventilated place away from heat and fire sources; The shelf life is one year at 25 ℃ and 6 months at 25 ~ 35 ℃.