Various sand control technical systems are designed according to different conditions of each stratum and block:

1. The loose sand stratum put into production of the new well and the fine silt mud in the deep stratum cause the formation to be blocked. The combined process of plug removal and sand control can stabilize and restrain the sand at the distal end of the formation, reduce the particle migration and prevent the formation from being blocked.

2. Stratum produces silt and large grain quartz sand, near-well stratum produces serious sand, fracturing sand of fracturing well reversely emits sand, far stable near-solid aggregate sand control uses oil production sand control agent to aggregate distal fine sand into sand ball, and then uses resin sand consolidation agent to solidify near-well stratum sand, so as to strengthen reservoir consolidation strength in near-well zone.

3. For sand producing well with large area of stratum deficit due to serious sand production of stratum, resin sand shall be used for high pressure filling of artificial well wall filled with sand gravel to establish high-strength artificial well wall.

1.Sand Control Agent for Oil Production Polycation

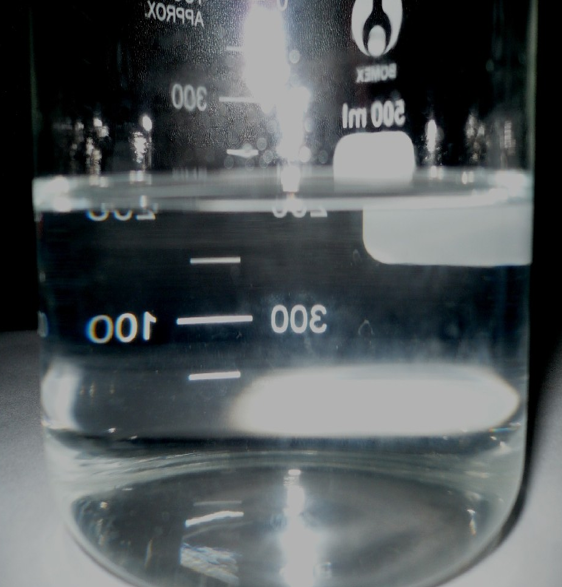

The organic polymer system is mainly developed for the particle migration during the development and production of loose sandstone reservoirs. The working principle is as follows: after the product solution is injected into the formation, the semi-crosslinked network molecules are uniformly distributed on the pore surface of the formation through electrostatic adsorption. Under the conditions of formation temperature and pressure, the components of JSFS-IV sand control agent for oil production continue to be crosslinked and copolymerized to form a high molecular network structure with high strength. Relying on the positive electricity of the molecular surface, the molecules are closely adsorbed on the negative electricity surface of the particles, At the same time, loose particles are bridged, to stabilize the particles that have occurred and will be transported.

This product can be used alone as an anti-swelling agent in daily well flushing and pump inspection, or as a pre-fluid and post-top fluid in plug removal and sand control measures, which can significantly extend the normal production time of the oil well.

Applicable scope:

1. Formation mud and fine silt.

2. The formation framework has not been damaged, but particle migration has occurred.

3. Deep stratum sand production.

advantage

1) The experiment shows that when the scour displacement reaches 7000ml/h, the outlet sand content is less than 0.005g/L, which is much better than the ordinary sand suppressant.

(2) Simple construction: prepare a certain concentration of water solution according to the design requirements on site and squeeze it into the formation for several hours of shut-in reaction.

(3) Wide range of applicability, applicable to all sand production wells except steam injection thermal production wells.

(4) High construction safety, even if the agent is retained in the wellbore, it will not affect the safety of the construction string.

(5) High permeability retention. Due to the inherent characteristics of oil production sand control agent, the pore will not be blocked, and the high permeability of the reservoir can be maintained.

2.Oil-based resin sand consolidation agent

it is an organic resin system developed mainly for the particle separation from the formation framework migration during the development and production of loose sandstone reservoirs. Condensation reaction occurs between resins, forming a three-dimensional network structure, and improving reservoir cementing strength to achieve sand control.

The oil-based resin sand fixing agent and curing agent are uniform liquid, with low viscosity, good mobility and wide temperature range (30-150 ℃). The obvious feature is that it overcomes the disadvantage that other sand consolidation agents have great damage to the formation permeability. After being injected into the formation, the strong groups in the molecules have affinity to the sand groups and can generate strong adsorption on the sand surface.

During the curing process of the sand fixing liquid, strong acidic curing agent or internal curing agent can be used to make it polymerize quickly to bond the sand particles together.

With the progress of polymerization reaction, the viscosity of resin rises, linear macromolecules become shape network macromolecules, and the strength of the product is not more obvious than the hydrophobicity of the product. It has poor adsorption on the tubing, casing, sand control screen pipe, etc. in the oil well, and does not block the screen hole. It is suitable for the chemical sand fixation of the oil well with screen completion and the sand production oil well with mechanical sand control.

Application scope of oil-based resin sand consolidation agent

1. Silt and large grain quartz sand are produced in the stratum.

2. The formation framework is damaged, and particle shedding, and migration occur.

3. Seriou’s sand production of near-well stratum; Wells unable to perform normal operation due to serious sand production;

4. Fracturing sand from fracturing well.

5. For wells with signs of sand production and requiring a large amount of fluid extraction, the wall of the near-well zone shall be reinforced in advance.

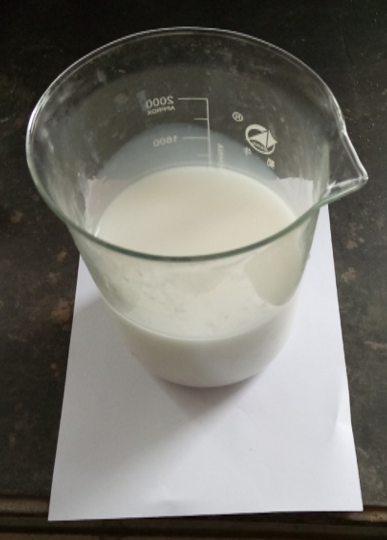

3、 Water-based resin sand consolidation liquid

Water-based resin sand consolidation fluid is a cheap and high-performance sand consolidation agent mainly developed for sand producing oil and water wells with thick oil layers, long well sections and large treatment radius in loose sandstone reservoirs. It is composed of resin, internal curing agent, co-solvent and pore expanding fluid.

It is mainly used for the early chemical sand control of new production well and new reperforating well without loss of formation, and the overhaul well with casing leakage and formation collapse that cannot be repaired. It is applicable to vertical well, inclined well and sidetracked well with reservoir temperature of 500C-700C. The sand control process using this material is simple, safe, successful and has a long period of validity.

The product is a thermoset reactive resin. The product is a bicomponent, one part is a resin component, and the other part is a curing agent component. During construction, the two components shall be fully mixed on the ground, pumped into the sand production horizon by pump truck, and then replaced with 5 times of clean water. Upon the completion of construction, the well can be shut in and consolidated for 48 hours before putting into production. The resin sand fixing agent has excellent acid and alkali resistance; At the same time, the viscosity of the product is low, the permeability is strong, and the consolidation strength is greatly improved.

Scope of application

1. Early chemical sand control for new production and new reperforating horizontal wells without formation loss.

2. Long interval oil well with small total sand production, but sand-buried oil layer in short-term production process.

3. Well with cement seal or constructed by single fluid method.

Product advantages:

(1) Compared with other resin sand fixatives, water-based resin curing liquid has the characteristics of low dosage, controllable curing time, and the compressive strength of consolidation body can meet the production requirements.

(2) The water-based resin curing liquid is used, and the compressive strength of the consolidation body can reach about 2.5 MPa, and the permeability retention rate is more than 75%.

(3) The water-based resin curing fluid is applicable to the curing temperature of above 30 ℃, the curing time of 24~48 hours, the formation fluid immersion resistance, and the conditions of low-temperature oilfield oil layers.

(4) The solidification speed of water-based resin curing fluid can be adjusted in a large range. It can be used for sand consolidation of single-layer well and layered chemical sand control in the field, solving the sand control problems of some long well sections and multi-layer wells, and providing a set of feasible and low-cost sand control methods for long well section sand control.

Resin coated sand for high strength sand control: including coated quartz sand and coated ceramist is a new generation of coated sand developed because of various advantages of currently coated sand in China. It is applicable to sand control of various oil and water wells. It is loose under normal temperature. During construction, sand carrying fluid is used to carry it into sand producing horizon. Artificial well wall with high strength and permeability can be formed under formation temperature, to achieve sand control.

Applicable scope:

1. Sand production well with serious sand production of stratum resulting in large area of stratum deficit.

2.Fracturing sand reverse flow of fracturing well leads to near well formation deficit.