In the production process of steel enterprises, a certain amount of iron-bearing waste materials is generated. Many steel plants utilize these iron-containing wastes in sinter production. These materials are rich in iron and alkaline oxides, which can improve the grade of sintered ore and reduce the consumption of fuel and flux.

Mill scale is an oxide that peels off the surface of steel products when they are rapidly cooled by water during high-temperature rolling. It accounts for about 2% of steel production and has a total iron content of over 70%. During sintering, mill scale undergoes exothermic oxidation, which helps save fuel. Currently, mill scale is fully utilized in China's steel industry, primarily as a raw material for sintering and as a cooling agent in steelmaking.

Steel slag is a molten slag discharged during the steelmaking process and is a by-product of steel production. The generation rate of steel slag is about 10%-15% of crude steel output. It mainly originates from oxides formed by elements such as silicon, manganese, phosphorus, and a small amount of iron oxidation in metallic charge materials, as well as fluxing agents added to adjust slag properties, such as limestone, dolomite, fluorite, and silica. Currently, the primary steelmaking methods in China are converter and electric furnace steelmaking, with converter steelmaking accounting for 80% of production. Converter slag constitutes the main component of steel slag. In sinter production, steel slag undergoes exothermic oxidation, reducing fuel consumption. Additionally, steel slag has high water absorption, and its particle size distribution facilitates pelletization. The addition of steel slag improves the initial permeability of the mixed materials. Moreover, steel slag contains a relatively high phosphorus content, which increases the phosphorus content in sintered ore and reduces its natural pulverization. Thus, the use of steel slag not only enhances the output and quality of sintered ore but also saves fuel.

Steel slag and mill scale pellets are produced by mixing steel slag and mill scale in any proportion (e.g., 3:7, 4:6, or 5:5), adding JS powder binder, and pressing them into balls. This approach maximizes the internal recycling of iron-bearing resources within the unit, reduces the consumption of fuel and flux in sinter production, lowers the cost of sintered ore, and creates significant profit margins.

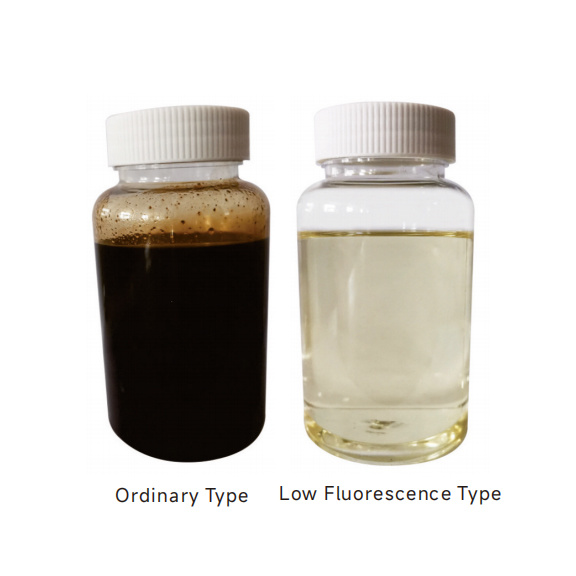

1. Advantages of JS slag iron ore pellet binder:

1) Low addition amount: Added to the slag iron ore mixture at a ratio of 1-2%, 1 ton of binder can produce 50-100 tons of finished pellets.

2) Easy to use: This binder is in powder form and can be directly added to the material, mixed with water evenly, and pressed into pellets.

3) Excellent performance: One-time molding with a molding rate of over 90%. Wet pellets can fall from a height of 2 meters without scattering, and can be naturally dried or oven dried. After drying, the strength can reach about 1500N.

4) No degradation of grade: The binder does not contain harmful elements such as silicon, aluminum, sulfur, or phosphorus that are detrimental to steelmaking and ironmaking, thus it does not degrade the grade of the pellets and does not increase any ash content.

II. Usage Method:

1) Add the dry powder binder evenly into the material according to the ratio, with varying amounts based on the material's particle size and specific surface area.

2) Moisten the material by spraying an appropriate amount of water according to the moisture level of the material. Be careful to control the humidity. If the material is too wet, it may easily stick to the mold and reduce the balling rate.

3) Use a roller mill to mix evenly, then convey it via a belt to the ball press to form pellets.

3. Example of application site:

IV. Our Advantages:

1. Equipped with professional laboratories, we can mix and produce the most cost-effective products for different materials.

2. Before the products are sold, specialized technical service personnel can be dispatched for on-site testing as needed.

3. High-quality after-sales service, with professional technicians sent to provide on-site guidance after the products are sold.

Keywords

Download

JS steel slag iron ore ball binder

Contact Us

Classification