High-grade iron block ore can be directly charged into the furnace for iron smelting, while iron powder must be pressed into shape before it can be smelted. Therefore, the forming process is very important for the subsequent use of iron powder, where the type and dosage of the binder are crucial.

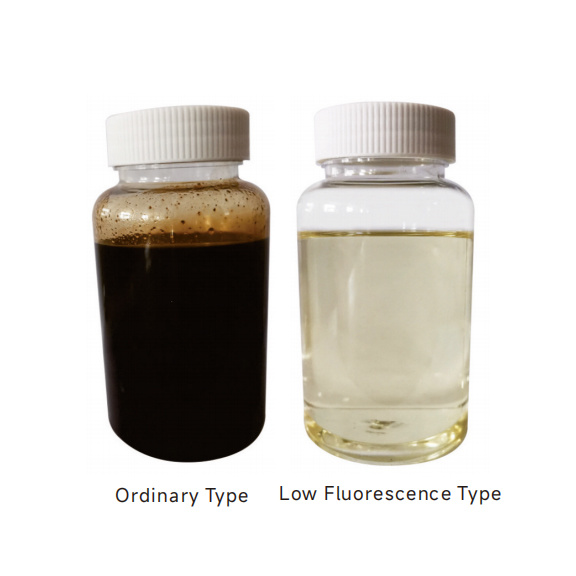

Traditional inorganic binders are characterized by their low cost, good thermal stability, and relatively high strength of the produced dry pellets. However, the inorganic impurity elements they introduce can lead to pellet impoverishment, and may even degrade the metallurgical properties of the product, while also causing environmental pollution. The JS iron powder pellet binder developed and produced by our company is an organic binder that not only typically possesses high viscosity at room temperature but also has very high binding strength after drying. Moreover, the organic binder burns off during the pellet roasting process, which does not adversely affect the quality of the pellets and the grade of metallized pellets, showing great application potential in the pressing and forming of iron powder pellets.

1. Advantages of JS iron powder pellet binder:

1) Low addition amount: added at a ratio of 1-2% to iron powder material, 1 ton of binder can produce 50-100 tons of finished pellets.

2) Easy to use: this binder is in powder form, which can be directly added to the material, mixed with water, and pressed into balls.

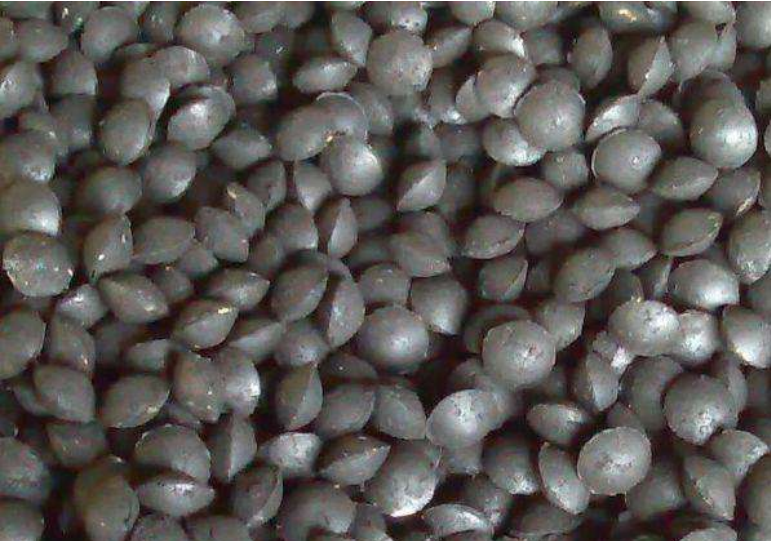

3) Excellent performance: one-time forming with a forming rate of over 90%, wet balls can fall from 2 meters without disintegrating, and can be naturally dried or dried in a dryer, with a strength of around 1500N after drying.

4) No downgrade in quality: the binder does not contain harmful elements for steelmaking and ironmaking such as silicon, aluminum, sulfur, and phosphorus, does not lower the pellet grade, and does not add any ash content.

2. Usage method:

1) Use a proportional amount of dry powder binder and evenly mix it into the material, varying the binder amount according to the material's particle size and specific surface area.

2) Moisten the material, spraying an appropriate amount of water depending on the humidity of the material. Control humidity carefully; too much moisture can lead to mold sticking and a lower ball forming rate.

3) Mix evenly in a roller mill, then transfer via conveyor to the ball press for pressing.

3. Example application scene:

4. Our advantages:

1) We have a professional laboratory capable of formulating the most cost-effective products for different materials.

2) Before the product is sold, we can dispatch specialized technical service personnel for on-site experiments as needed.

3) Excellent after-sales service, where professional technicians will be sent to guide the usage of the product after sale.

Keywords

Download

JS Iron Concentrate Pellets Binder

Contact Us

Classification