With the rapid development of the steel industry in our country, society is increasingly concerned about resource and environmental issues. Effectively managing and utilizing dust from steel plants to achieve clean production will undoubtedly be an important goal for the healthy development of the steel industry in our country in the future.

Converter dust is produced during the blowing process of the converter, where a large amount of iron-containing dust is blown away and enters the dust removal system via the flue, containing iron elements (TFe≥50%), active calcium oxide (15-20%), and trace alloy resources such as zinc; blast furnace ash is a very fine sludge obtained from the dry dust removal of blast furnaces at ironworks and the sedimentation of wastewater discharged from gas washing into a settling tank, where the occurrence of blast furnace dust is generally 15-50 kilograms per ton, mainly composed of carbon, iron oxides, and valuable metals; electric furnace dust is the flue dust produced by processing scrap steel using electric arc furnaces or medium-frequency furnaces, generating 12-20 kilograms of electric furnace ash for every ton of scrap steel processed.

Converter ash (can add 10-30% of iron scraps), blast furnace ash, and electric furnace ash are used to produce cold-bound pellets for reuse, recovering valuable elements such as zinc, lead, iron, and carbon, preventing environmental pollution and generating economic benefits, achieving the recycling of by-products in the metallurgical industry.

1. Advantages of JS converter ash, blast furnace ash, and electric furnace ash binders:

1) Low addition amount: Solid powders and liquid binders are added to materials at about 3% ratio, allowing 1 ton of binder to produce 30-50 tons of finished pellets.

2) Convenient use: Solid powders and liquid binders are directly added to the materials, with appropriate water added for even mixing, allowing them to be pressed into balls.

3) Excellent performance: One-time molding with a molding rate exceeding 90%, wet balls can fall from 1.5 meters without dispersing, can be naturally dried or baked, with strengths of around 1200N after drying.

4) No downgrade of grade: The binder contains no harmful elements such as silica, aluminum, sulfur, or phosphorus that affect steel and iron making, maintaining pellet quality without increasing any ash, making it an environmentally friendly binder.

2. Usage method:

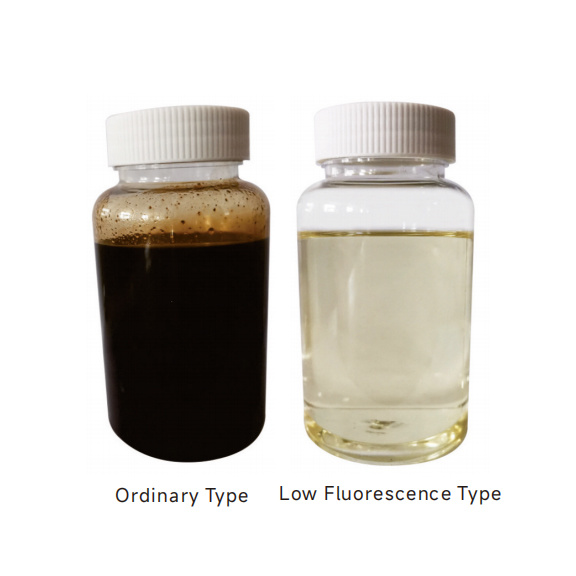

Our company has developed and produced JS converter ash, blast furnace ash, and electric furnace ash binders in both solid powder and liquid forms, with specific usage methods as follows:

1) Method for using solid powder binders:

(1) Uniformly add dry powder binder into the material according to the mixing ratio, with different amounts based on the material particle size and specific surface area.

(2) Wet the material, spraying an appropriate amount of water depending on the material's humidity. Care should be taken to control humidity; excessive moisture can lead to mold sticking and reduced pellet yield.

(3) The wheel mill mixes evenly, and the mixture is sent to a pellet press via belt for pressing into pellets.

2) Method for using liquid binders:

(1) Binder preparation: Combine our produced A agent and B agent in a certain ratio, using water as a medium to prepare the liquid binder.

(2) Add the prepared binder to the material in a certain proportion.

(3) The wheel mill mixes evenly, and the mixture is sent to a pellet press via belt for pressing into pellets.

3. Examples of application sites:

4. Our advantages:

1) A supporting professional laboratory that can tailor the most cost-effective products for different materials.

2) Before the product is sold, specialized technical service personnel can be sent for on-site experiments if needed.

3) High-quality after-sales service, with professional technicians dispatched to offer on-site guidance after the product is sold.

Keywords

Download

JS converter slag, blast furnace slag, electric ash binder

Contact Us

Classification