Research has found that lignite produces better quality in metallurgical fields such as metallurgy, calcium carbide, and ferrosilicon than ordinary coke. Additionally, using lignite as fuel has significant implications for reducing enterprise costs and production energy consumption. In recent years, lignite has also begun to be used in blast furnace blowing and as fuel for sintering, achieving good results. With the rapid development of steel enterprises, the price of coke has been climbing year by year. Furthermore, the recent shortage of coal resources has made lignite, as an inexpensive carbon material, increasingly favored by the metallurgical industry. Replacing coke and coal with lignite in metallurgical production not only reduces production costs to a certain extent but also effectively alleviates the problem of tight coal resources.

Coke is the main fuel in the iron-making industry, but coke is brittle, and there is a large amount of inexpensive coke powder available. A high content of coke powder in the iron-making fuel inevitably affects the permeability in the furnace during iron-making, thus it is necessary to granulate coke powder. Currently, coke powder can only be formed using cold binding methods, where the key technical challenge is the development of binding agents.

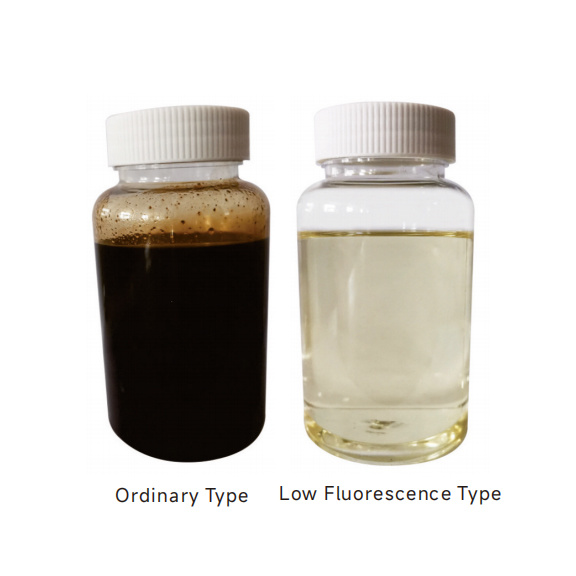

Our company has independently developed and produced JS lignite and coke powder binding agents for the processing of lignite balls and coke powder balls, suitable for small blast furnaces for iron-making, metallurgical flux, chemical gas, and calcium carbide production industries to partially replace coke.

1. Advantages of JS Lantan and Coke Powder Binders:

1) Low addition amount: Added to Lantan and coke powder materials at a ratio of 2-3%, 1 ton of binder can produce 30-50 tons of finished pellets.

2) Convenient to use: This binder is a powdered solid that can be directly added to the materials, mixed evenly with water, and pressed into pellets.

3) Excellent performance: One-time forming, with a forming rate of over 95%, a wet ball can fall from 2 meters without disintegrating, and can dry naturally or be oven dried. After drying, it can withstand free fall from 2 meters more than 3 times, resistant to high temperatures, and does not break or powder at 1000°C.

4) Low fluctuation of fixed carbon: The binder contains no harmful elements such as magnesium, aluminum, iron, or phosphorus, resulting in a small reduction in fixed carbon content without increasing any ash content.

2. Method of use:

1) Evenly add the dry powder binder to the material according to the ratio. The amount of binder added may vary depending on the particle size and specific surface area of the material. If the material particles are larger, they should be appropriately crushed.

2) Moisten the material by spraying an appropriate amount of water according to the moisture condition of the material. Be sure to control the moisture level. If the material is too wet, it may cause sticking to the mold and reduce the pelletization rate.

3) Use a roller mill to mix evenly, then convey it to the briquette press via a belt conveyor, and it can be pressed into pellets.

3. Example of application site:

IV. Our Advantages:

1) Equipped with professional laboratories, we can mix and produce the most cost-effective products for different materials.

2) Before the products are sold, specialized technical service personnel can be dispatched for on-site testing as needed.

3) High-quality after-sales service, with professional technicians sent to provide on-site guidance after the products are sold.

Keywords

Download

JS lignite, coke powder binder

Contact Us

Classification